Marking a big step forward towards launch, all ten of the powerful solid rocket booster (SRB) segments for NASA’s inaugural Space Launch System (SLS) rocket liftoff on the Artemis 1 Moon mission arrived by a train Monday afternoon at NASA’s Kennedy Space Center in Florida – thereby completing a 10-day cross country rail journey from their Northrop Grumman manufacturing facility in Promontory, Utah.

Furthermore, it has been 10 years since the last SRBs arrived at KSC for the final NASA Space Shuttle mission.

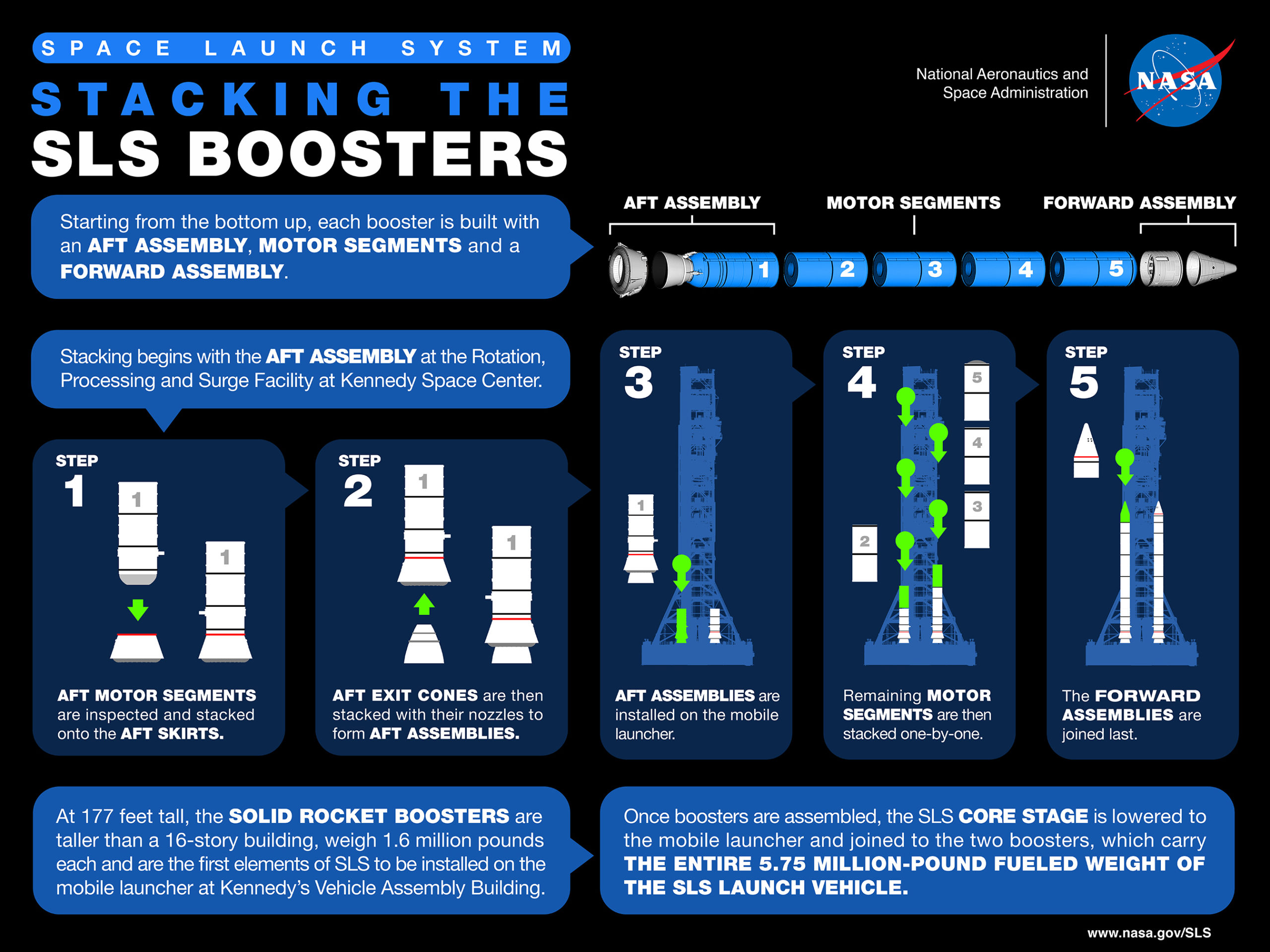

After the ten 10 SRB segments are stacked vertically they will form the two twin 177-foot-tall (53.9-meter) five-segment Solid Rocket Boosters for NASA’s gargantuan SLS Moon/Mars rocket.

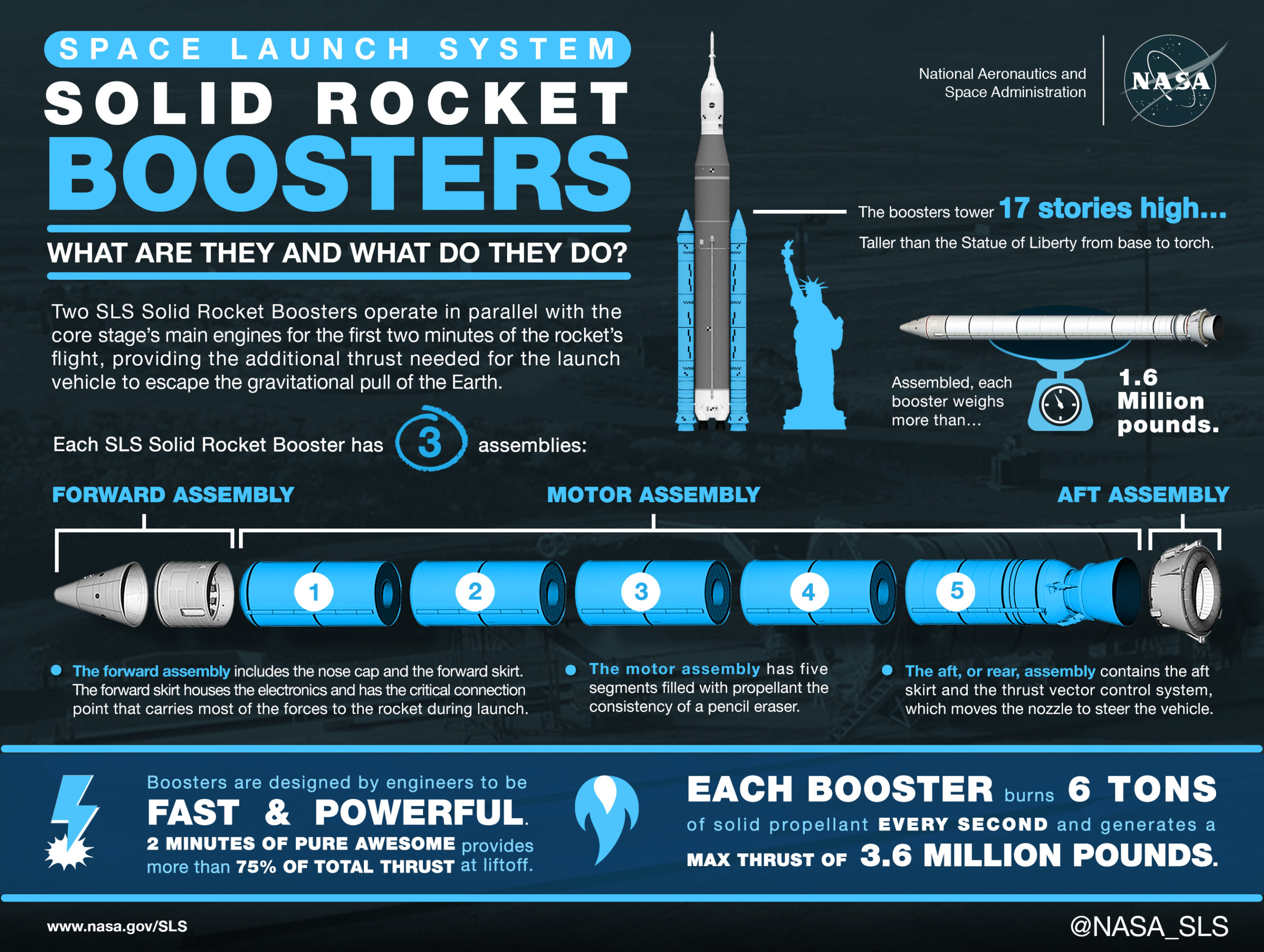

Together the twin SRBs will provide more than 75% of the liftoff thrust for NASA’s Space Launch System (SLS) megarocket that will propel NASA’s Orion deep-space crew capsule on its first uncrewed test flight to the Moon on the Artemis 1 mission – currently slated to launch later in 2021.

Each of the 10 SRB segments weighs 180 tons was loaded individually onto a specially designed railcar that was pulled by the ‘Shuttlewagon’ locomotive. They departed Utah on June 5, 2020, for the 2800 mile trek across eight states to Florida’s Space Coast.

I observed the arrival by train of the booster segments Monday, June 15 – first as they passed over the Jay Jay railroad bridge over the Indian River in Mims around noon time EDT, and then up close when they arrived at the north entrance to KSC around 5 p.m. EDT with one media colleague and a few NASA KSC representatives.

Altogether it took about three minutes for the ‘Shuttle Wagon’ locomotive to haul the 10 SRB loaded railcars past us.

That same ‘Shuttle Wagon’ brought the last SRBs to KSC was 10 years ago in 2010 for the final shuttle launch STS-135 – and I was on hand for that delivery also.

NASA’s goal under Project Artemis is to land the first woman and next man on the lunar south pole surface by 2024 during the Artemis 3 mission when a crew of astronauts will launch in the Orion Crew Capsule atop the mammoth Space Launch System rocket – currently under development by NASA.

The SLS rocket and Orion Crew Capsule have been under development for a decade.

“The arrival of the booster segments at Kennedy is just the beginning of the SLS rocket’s journey to the pad and onward to send the Orion spacecraft to the Moon,“ said NASA Administrator Jim Bridenstine, in a statement.

“Artemis I will pave the way toward landing the first woman and the next man on the surface of the Moon in 2024 and expanding human exploration to Mars.”

Each of the SLS SRB’s is comprised of five segments that will generate 3.6 million pounds of liftoff thrust – that’s equivalent to more thrust than 14 four-engine jumbo commercial airliners.

Thus the twin five-segment SLS SRBs will provide a total of 7.2 million pounds of thrust.

The solid rocket booster segments for @NASA_SLS have arrived @NASAKennedy ahead of the first #Artemis mission. This is a major milestone for @NASA and @NASAGroundSys as we prepare to send the first woman and next man to the Moon by 2024: https://t.co/jIUoo3Lhw9 pic.twitter.com/QY5ymzk60h

— Jim Bridenstine (@JimBridenstine) June 16, 2020

When fully assembled and fueled with polybutadiene acrylonitrile (PBAN) each booster is 17 stories tall and 12 feet in diameter and weighs 1.6 million pounds.

After passing through the KSC security gates the ‘Shuttle Wagon’ train hauled the 10 railcars right past NASA’s iconic Vehicle Assembly Building (VAB) to arrive at Kennedy’s Rotation, Processing and Surge Facility (RPSF).

“The Shuttle Wagon that once brought the space shuttle boosters onto Kennedy along the same tracks delivered the rocket motors to the center’s Rotation, Processing and Surge Facility (RPSF).”

The booster segments will remain in the RPSF for inspection prior to processing until it’s time to move them to the Vehicle Assembly Building for stacking on the mobile launcher.

“It’s an exciting time at NASA’s Kennedy Space Center as we welcome Artemis flight hardware and continue working toward the Artemis I launch,” said Kennedy Space Center Director Bob Cabana.

When launched the SLS SRBs will fire for just over 2 minutes or 126 seconds while burning approximately six tons of propellant every second.

The SLS boosters are based on and derived from the space shuttle SRB’s which were comprised of 4 segments and generated 3 million pounds of thrust each.

For SLS a number of design and performance improvements have been instituted by the manufacturer Northrop Grumman.

“New technologies and material upgrades enable the boosters to meet the high-performance demands of SLS, the most powerful rocket NASA has built to date,” said Charlie Precourt, vice president, propulsion systems, Northrop Grumman, in a statement. “Our technology will help propel the first woman and the next man to the moon.”

Each SRB has five individual motor segments, located between the forward assemblies and aft skirts, making up the largest single component of the entire booster.

“The solid rocket boosters are the first elements of the SLS rocket to be installed on the mobile launcher in preparation for launch. The aft booster assemblies will be lifted on to the mobile launcher, followed by the remaining booster segments, and then topped with the forward assembly,” according to NASA officials.

SLS is the most powerful rocket ever built. The rocket’s core stage was built at NASA’s Michoud Assembly Facility in New Orleans and is the largest rocket stage the agency has built since the Saturn V that sent Apollo astronauts to the Moon.

The SLS core stage is currently in the test stand at NASA’s Stennis Space Center near Bay St. Louis, Mississippi where it is being readied for the critical Green Run full duration hot-fire test later this year.

Thereafter it will be transported to Kennedy by the Pegasus barge for integration with the SRBs and Orion.

The twin SRB boosters will eventually be attached to the SLS core stage on the Mobile Launcher.

SLS and Orion will launch off Launch Complex-39B at NASA’s Kennedy Space Center which has been extensively upgraded to support the new Heavy Lift rocket.