Neil Armstrong set the first distance record with an impromptu amble to Little West crater. Pete Conrad and Alan Bean exceeded that several times over by circling out and down into Surveyor Crater. Edgar Mitchell still holds the title for longest one, over a mile, made when he and Alan Shepard went looking for Cone Crater.

The Lunar Reconnaissance Orbiter photos tell the stories: for Apollo 11, 12 and 14, the dark trails scuffed in the dust show tentative explorations in this most dangerous place, where even a short hike was risky, and time was always precious. They were Moon walks, and triumphant as they were, they were frustratingly limited.

The astronauts on the first three lunar landings crossed a quarter-million miles of space to investigate, at most, a few hundred yards of the lunar surface. Something more was needed to turn Apollo into real exploration.

Out of the Cold War

The science fiction vision of driving on the Moon actually preceded the fact of driving on the Earth. It turned real as the space race accelerated. Cold War fear was an impetus as much as peaceful scientific curiosity.

Military contractors such as Grumman, Northrop and Boeing, already involved in lunar spacecraft design, created speculations on lunar surface vehicles of all configurations—one-man, two-man, long traverse, short-hop, rolling RV-sized habitations (the Mobile Laboratory, “MOLAB”) that could carry multiple crew and operate autonomously for weeks at a time; even a rocket-belt that would boost an astronaut on twin hand-controlled jets.

Billions of dollars were at stake, both for Apollo and for the permanently-based militarized Moon that the Pentagon envisioned in its 1959 proposal for Project Horizon: “The lunar outpost is required to develop and protect potential United States interests on the Moon; to develop techniques in Moon-based surveillance of the earth and space, in communications relay, and in operations on the surface of the Moon; to serve as a base for exploration of the Moon, for further exploration into space and for military operations on the Moon if required; and to support scientific investigations on the Moon.”

The ambition boggled minds and budgets: they set a deadline of 1966 to open the base, and planned expansion in 1967 requiring a launch schedule of over 200 Saturn I and II boosters, a new launch complex on the Equator; and a Vehicle Assembly Building at Cape Canaveral with six support bays for Apollo launch vehicles.)

This was the Cold War crystallized: money was no object and the Earth was not big enough for it. Not surprisingly, General Motors Defense Research Laboratories (GMDRL) a wing of one of the most powerful companies in history as the space race gained momentum, wanted in.

Mieczyslaw Bekker was head of the Mobility Research Laboratory at GMDRL. Born in Poland 1905 and graduated from Warsaw Technical University in 1929, Bekker had worked for the Polish Ministry of Military Affairs, doing pioneering research off-road traction for tracked vehicles.

The German invasion of Poland forced his group to flee to Romania and then, in 1939, to France, where in 1942 the government of Canada offered him a chance to move to Ottawa. After 13 years in the Canadian army, he retired and in 1956 moved to the United States.

Bekker’s 1956 Theory of land locomotion: the mechanics of vehicle mobility was a forerunner of engineering in off-road vehicles that would help lead in the development of their ultimate expressions. In 1956, Bekker was hunting for talent. As a former refugee himself, he knew where to look.

Ferenc Pavlics

Ferenc Pavlics was newly-arrived in the United States. He and his wife had made a harrowing escape from Hungary after the uprising that had nearly thrown off Soviet control and then provoked a vicious response from Moscow.

Pavlics had been working as a design engineer at the Machine Industry Design Institute in Budapest and teaching at night at the Technical University of Budapest. He and his wife crossed the border into Austria past canine patrols and Soviet soldiers. Pavlics was carrying his own KGB file; had he been caught they would surely have been severely punished.

After months of waiting and uncertainty, the Pavlics committed themselves to go to America, and along with 4,000 of their countrymen, they boarded a re-commissioned World War II troop carrier.

Almost 40,000 refugees were received in Camp Kilmer, a reactivated military base in New Jersey. Bekker found a trove of talented engineers there, and within a week Ferenc Pavlics was on his way to a GM job in Detroit. In 1960 GM moved the Defense Research Laboratories to Santa Barbara, with lunar vehicles on the agenda, and wheeled tracks in the lunar regolith—possibly—just a few years away.

Limited time, many questions

It is worth reminding ourselves how little was actually known about the Moon at the time. The most effective exploratory tool in 1960 was the same one Galileo had used three centuries earlier: the telescope.

Pavlics and his colleagues were designing for a surface whose nature they did not know. Scientists such as Cornell’s Dr. Thomas Gold speculated that it might not be a “surface” at all, just a thick, soft layer of dust that would engulf anything that touched it. To cope with that, some early ideas from GMDRL and its competitors featured fat balloon tires, huge spring wheels and even an idea for a version of an Archimedean screw that would burrow through a deep layer of dust.

The learning curve started with unmanned landers. GM collaborated with the nearby Jet Propulsion Laboratory in Pasadena, where planning for JPL’s Surveyor lunar soft-lander was underway.

In 1963 Bekker and Pavlics offered a proposal for a tiny six-wheeled solar-powered vehicle that would ride down to the Moon aboard Surveyor and then slither down off it onto the surface. That never materialized, but it did offer both GM and JPL a starting point. (General Motors’ wire-tire idea started there, later to blossom with the ones on the Apollo Rovers; and JPL’s confrontation with the need for pitch and roll in a roving vehicle led them eventually to the rocker-bogie solution first used on the Mars Pathfinder Sojourner.

Month-by-month and mission-by-mission the nature of the surface was revealed, and it proved have the bearing strength required for the ambitious vehicle designs being created by NASA and its contractors.

GM’s people were just a fraction of the hundreds of thousands of engineers, designers and fabricators at contractors all over the United States who were building unprecedented hardware to impossible standards on breakneck schedules, and not a bolt on any of it was independent of everything else.

The question was not whether the Moon could carry the loads, but whether the boosters, the schedule and the taxpayers could bear them.

NASA still clung to visionary ideas out of Chesley Bonestell of pressurized rolling habitations but the ruthless standards of weight, time and money repeatedly took the blueprints off the table. It all had to work together.

All the farsighted ideas for lunar vehicles were feasible, but in the unforgiving context of the space race, none of them worked. They were too costly, too ambitious for the mission profiles, and above all just too heavy to carry. When reality was being measured in terms of grams and ever-tighter dollars, the lunar surface vehicle designers were still imagining in terms of tons, and eventually they had to concede the obvious. For Apollo, there would be no two-week surface expeditions, no separate Saturn cargo launches to place machines up there.

The need was bare-bones simple: aboard a single Saturn launch along with everything else needed for a mission, a vehicle that would be stripped to the minimum, used flawlessly but only once, and abandoned.

By 1967, when there were no realistic proposals on the table and the clock was ticking down to President Kennedy’s deadline, NASA said it could not be done.

But the hope was just too good for General Motors to leave behind, and the need was obvious. The most scientifically promising places on the Moon were also the most hazardous to reach; and what was the point of risking a landing at a site like the Apennines or Taurus-Littrow if the safe radius of walking exploration was half a mile around the LM?

However, developing a spacecraft took five years by the most optimistic schedule, and the ones for the Command Module and the Lunar Module had proven unrealistic. “This is 1967, 1968,” Pavlics remembered, “and it’s really late in the program to create a new vehicle that could be ready.

“North American already has to redesign the Command Module after the fire. The LM is behind schedule too. So NASA’s path is set. It was 1968 or so when they cancelled MOLAB and it looked like it was all done for vehicles. Then, independent research and development money provided by GM was used in our study—even if NASA did not want to pursue this, we still did.

“We did a study of how to create a vehicle to all the required specs and fit it either inside or attached to the outside of the existing LM. We went to NASA headquarters and talked with the brass and asked, can you identify what space might be available on the LM? We were also in contact with Grumman. They said, well, this small corner could be made available. Whatever was in there could be repositioned and the space freed up—we could use that much for whatever GM came up with. They we came home and started figuring it out.”

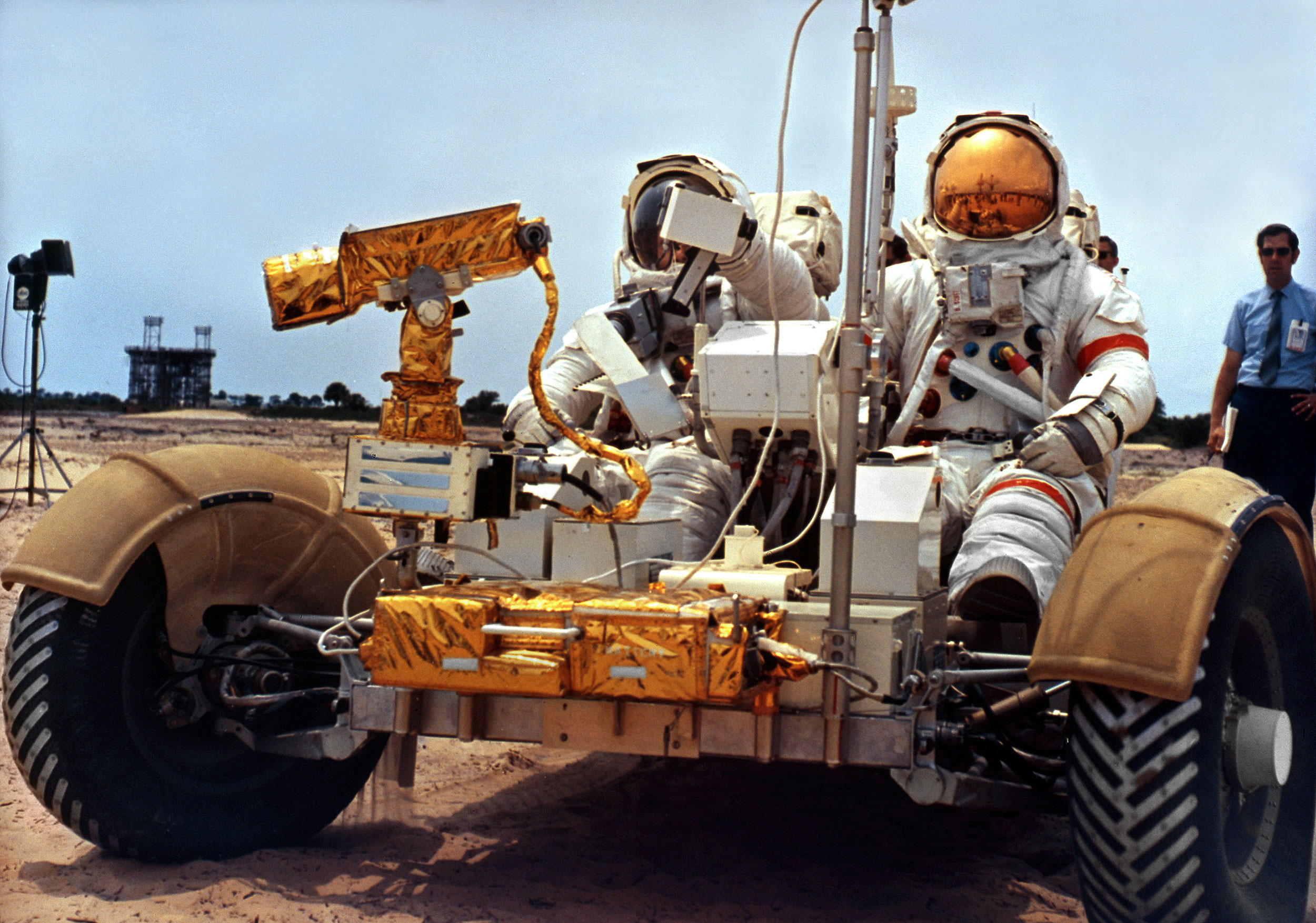

The “small corner” was inside the descent stage to the right of the ladder as one faces the LM. It was “a triangular bay 60 inches high, 70 inches wide at the base, and 36 inches deep”…. just over thirty cubic feet, and the shape of it narrowed from the broad end to a point like a tall, wide slice of layer cake. “Figuring it out,” as Pavlics put it, meant visualizing a way “to store a Jeep size vehicle carrying a payload of 1,200 pounds into a space not larger than the back of a station wagon.” The solution Pavlics figured out changed the Apollo program.

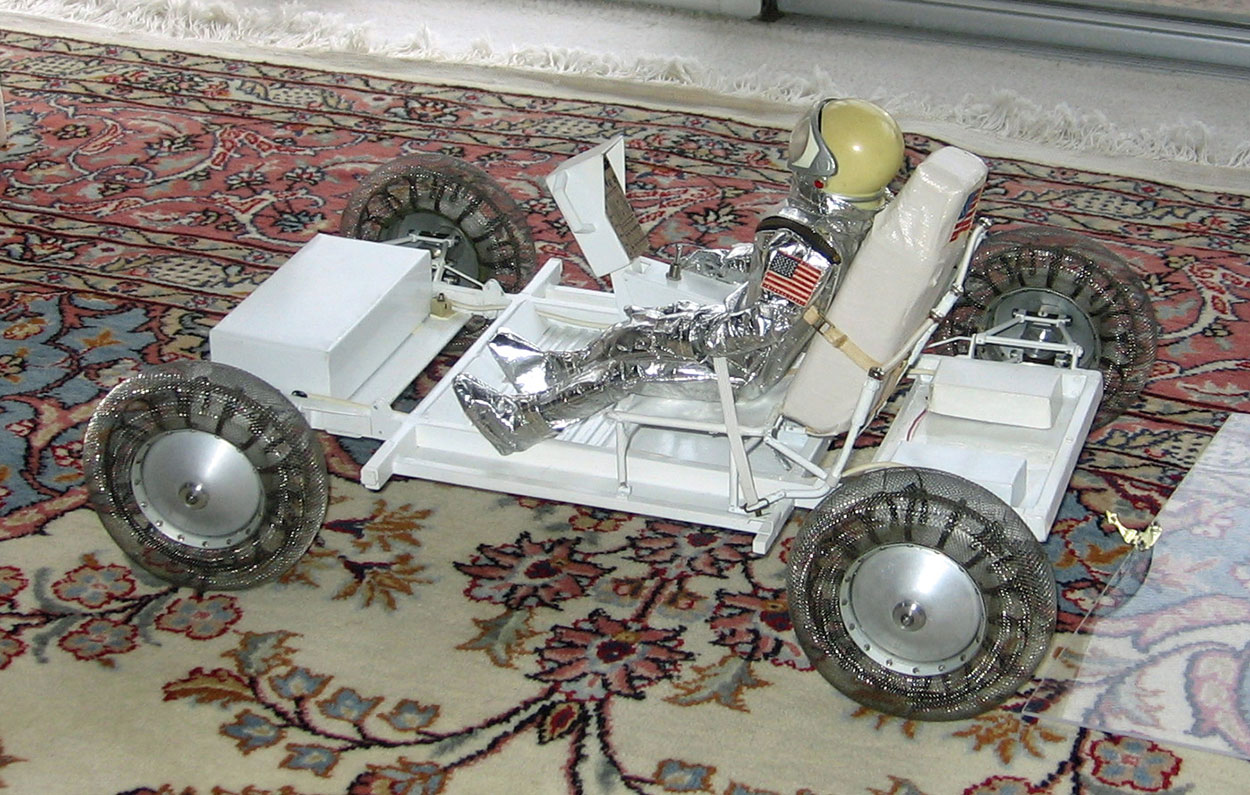

“I came up with this idea of folding the vehicle,” he said, “but nobody could really visualize it. That’s why I built a little 1/6 scale model and with that, people could see it. Some of the pieces that needed machining we did in the shop at GM, but I made most of it and assembled it here at home. [For the wheels] I bought some stainless steel mesh off the shelf and cut it to the right size, rolled it into a cylinder and then knitted the ends into a torus shape.

“The 1/6 scale was perfect for the passenger, an Astronaut G.I. Joe with a silver Mercury-type space suit that I borrowed from my son. My wife and I made an Apollo backpack. She helped to sew the folding seats. The instrument panel and the steering joystick, the wire wheels with the titanium bumpers, the folding seats, the way the front and rear sections folded up and the wheels tucked in; it was all accurate, all to scale. And it was radio-controlled, so you could unfold it, sit G. I. Joe in the seat, and drive it on the floor.

“GM knew I was doing it,” he continued, “but NASA was out of the loop. We were trying to sell the idea: look NASA, it’s possible to do this! We went to NASA headquarters, to Houston, and to Huntsville, and gave presentations demonstrating the model. We made a scale model of the space in which it had to fold, and showed how it worked.

“In Huntsville, we pitched the engineering group. One of them, Len Bradford, led the way to von Braun’s office and he opened von Braun’s door. Instead of going in, I put the model Rover on the floor. von Braun was on the phone and the model drove in over his rug. He hung up and said, ‘What the heck is this?’ We gave him the presentation of how it worked, how it folded. The week after, he called in [NASA Project Manager] Sonny Morea, and Morea became the program manager to develop the [Rover].

“NASA issued another Request for Proposals. GM bid against Bendix for the job; it was pro forma really, because our folding and packaging design couldn’t be duplicated. We got the contract and we and Sonny Morea had just 17 months to deliver the Rover.”

Specifications and pressure

It was to be a spacecraft every bit as much as were the CM, the LM and the EVA suits. Morea’s office specified as absolute the requirement that “no single point failure shall abort the mission and no second failure endanger the crew,” so regardless of the deceptive simplicity of it, and the casual sense of familiarity its design and the nicknames like “Moon buggy” invited, the LRV was subject to the same inviolable standards as all the rest of the Apollo hardware. The unprecedented challenges included creating a vehicle that had to:

- deploy safely in 1/6 G from the bay on the LM Descent Stage and be operable within 15 minutes or so;

- operate in a vacuum with temperatures between ±250 degrees Fahrenheit;

- permit ease of use by drivers wearing bulky protective suits;

- cross obstacles a foot high and over two feet deep;

- work without a transmission and gears, using instead four motors, one for each wheel, and operate if three of the four motors were out;

- permit the operators to venture miles from, and out of sight of, the Lunar Module while still being able to return to it in the minimal time, that is, not by retracing their path but by the most direct route;

- communicate via television and radio (voice and telemetry) with Houston in real time for the performance of both astronauts and the LRV, plus in support of the scientific objectives at each location visited;

- protect itself from temperature extremes and dust, and dissipate its own heat;

- weigh only about 450 pounds in 1G, about 75 in 1/6 G, and carry more than twice its weight;

- climb grades as steep as 25 degrees, and remain stationary when parked on a grade of 45 degrees;

- turn in a radius equal to its own length;

- provide real-time feedback on its condition to the operators and to Mission Control; isolate faults in its batteries and take corrective action; and

- deliver maximized freedom of movement for the greatest possible scientific exploration of every site.

It also had to do something no spacecraft to date had done: operate without ever having been tested under actual working conditions. Its first Apollo EVA would be its shakedown cruise, over two kilometers out in the Apennines past Rhysling and Elbow, then looping back along the gaping Rima Hadley on the way back with the lives of Dave Scott and Jim Irwin riding on it. The accelerated timeline was:

- May, 1968: GMDRL becomes AC-Electronics Defense Research Laboratories (AC-DRL).

- June, 1968: AC-E Defense Research Laboratory proposes packaging a disposable vehicle on the LM that can meet all the requirements and stay under weight constraints.

- May 23, 1969: NASA commits to the Lunar Roving Vehicle (LRV).

- June, 1969: Saviero Morea is put in charge of the Lunar Roving Vehicle Project Office at Marshall Space Flight Center in Huntsville.

- July 11, 1969: Morea’s office issues the RFP to 29 companies to build the LRV. They schedule a preliminary design review in ten weeks, and a critical design review in 22 weeks with contract approval.

- July 11- October 28, 1969: Morea’s office and team of engineers evaluate proposals from Grumman Aerospace, Chrysler Space Div., Bendix Corp, and the Boeing Co. It comes down to Bendix and Boeing with Boeing picked on October 28.

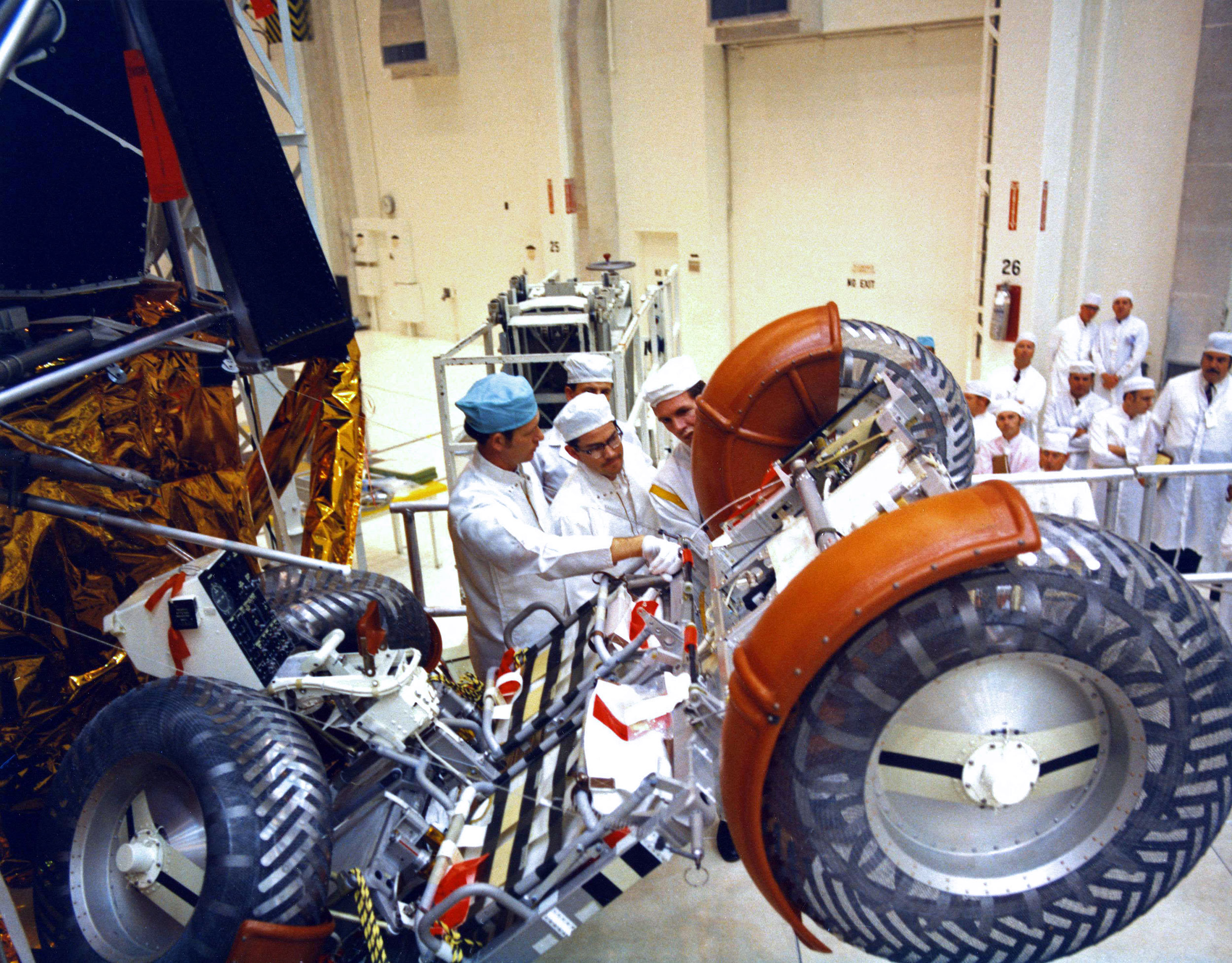

- October 28, 1969: MSFC announces Boeing as the winner and General Motors’s AC-Electronics Defense Research Laboratories as the prime subcontractor. Boeing has ten weeks to finalize the details of eight systems on it.

- January 18-19, 1970: All-hands preliminary design review at Marshall with 120 NASA, Boeing and other personnel and John Young, Gerald Carr and Charles Duke.

- June 16-17, 1970: Final certified design review at Marshall. The design is considered complete and production of the vehicles could proceed. ,

- July 26, 1971: Apollo 15 lifts off.

Rush, rush, rush

“When we got the contract,” Pavlics said, “we had less than 18 months to design, test and deliver the first Rover to NASA according to specifications for manned space flight. GM needed a partner for vacuum testing and conditions testing. We didn’t have those capabilities.

“GM didn’t have any background in space, after all. Boeing in Seattle did. We had partnered on MOLAB with Boeing and agreed on delineating duties.

“Boeing would handle the power system, navigation, communication and integration with the LM, and GM would do the vehicle itself including the chassis, wheels, suspension, steering, electric drive, controls and displays. We had some testing capability at GM but the qualification testing had to be done by Boeing. They had someone on site with us to ensure close communications. Both NASA and Boeing had a permanent presence here, in fact.

“That 18 months was rush rush rush,” he continued, “a nonlinear schedule of simultaneous systems development and testing in parallel. Fortunately, we had plenty of knowledge to leverage and lots of the hardware had been developed, so we weren’t starting from scratch. Also, we assigned parallel teams where each major subsystem had one engineer in charge—steering, traction and so on—and they were responsible for not just the design but carrying it all through testing and redesign and so on until delivery.

“In critical areas like electric drive, we had parallel and simultaneous development of alternatives, one with a DC drive and one with an AC drive, with the subcontractors. We knew we’d pick one, and we would commit to the best when the time came. That’s how we cut development time. We did experience test failures, and weight was a serious constraint. Every morning, my first meeting was a weight analysis meeting, with the engineers contending over every gram.

“This was a highly compressed schedule,” he said. “Nothing in Apollo had been started and stopped like this. It was day and night, weekends; our families hardly saw us. Nobody died, but some people got sick. But the great thing was, the people were so enthusiastic. You didn’t have to prompt people, or ask “Can you stay an extra hour today?” Everyone volunteered and worked together, 400 people from Santa Barbara working on this in a very enthusiastic team effort.

“NASA was following it very closely. I don’t think at the beginning they believed it. The top Apollo people seemed very dubious…Mueller, Low…Rocco Petrone seemed skeptical. This little outfit in Santa Barbara, no space experience; but the crew was testing the land version and training on how to be field geologists.[…] We made the deadline. It was delivered two weeks before the launch.”

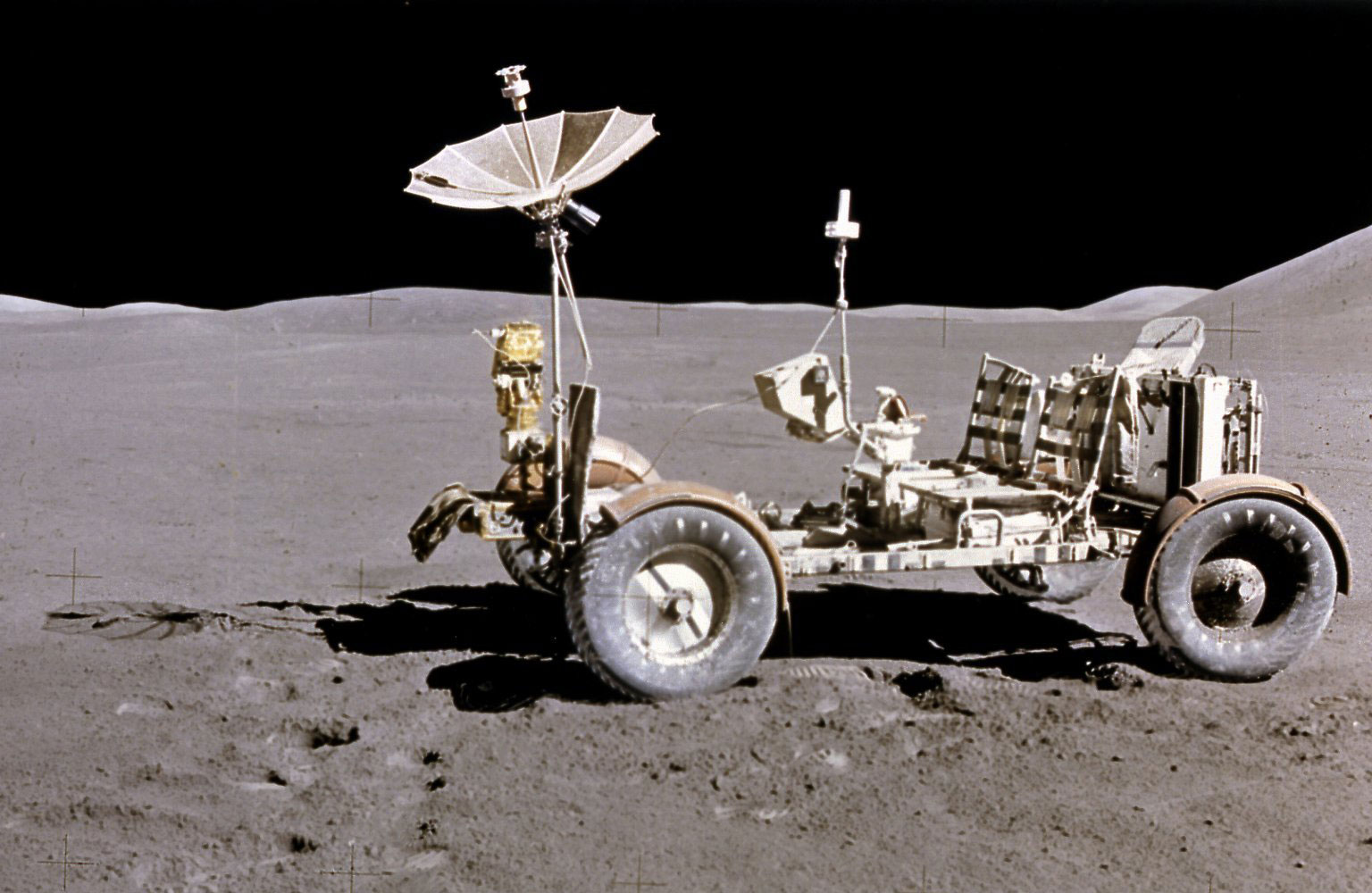

Wheels on the Moon

The Lunar Rover enabled the fulfillment of Apollo’s most ambitious promises. The difference it made can be seen in the Lunar Reconnaissance Orbiter photos of the landing sites for the last three Apollo missions.

Where their predecessors has covered yards, the J-mission landing crews covered miles–a total of 58–collecting over a quarter-ton of samples from multiple locations in fast but comprehensive surveys of the Marsh of Decay, the Descartes Highlands and the Taurus-Littrow Valley.

More than that, it may have saved Apollo entirely. After the near-disaster on 13, said Dave Scott, “the program was in serious trouble. It was behind schedule, over budget, and not satisfying its basic requirements.

By June 1970, two months after the near-loss of the Apollo 13 crew, termination of the program was being seriously considered.” Under pressure, with the budget cut, with the public losing interest and the scientific community demanding better results, NASA leaped ahead with voyages into more dangerous and interesting territory, with advanced equipment and the use of the LM as a base camp from which long traverses could be made, instead of as the sole determinant of the range of exploration.

With these began the true science of lunar exploration, and the process of learning how the Moon was formed.

“For our mission on Apollo 15, (as well as 16 and 17),” Scott continued, “the shift to a ‘J’ mission and the inclusion of the LRV meant that we could cover seven times the distance covered on ‘H’ missions. We would travel almost four times the distance from the LM, we would be able to carry many more tools, and we could collect and return twice the amount of surface rocks and soil.

“Further, because of the mobility of the LRV, we would be able to explore three different geological areas at our landing site, from a rille, to large craters, to the mountains; a true boon to the scientific exploration and comprehensive understanding of the Moon.” The “J “missions, said historians Charles Murray and Catherine Cox, were “magical”—“through them, planetary science was transformed.”

The author thanks Ferenc Pavlics and Dave Scott. This originally appeared in expanded form in “Quest, The History of Spaceflight Quarterly,” 18:1, 2011. Thanks to Scott Sacknoff, Publisher, and Dr. David Arnold.

This article appeared in the 12th issue of RocketSTEM.

Download PDF Issuu Reader Buy Print Edition

References

- Asnani, Vivake; Delap, Damon; and Creager. Colin “The Development of Wheels for the Lunar Roving Vehicle.” NASA/TM—2009-215798. Glenn Research Center, Cleveland, Ohio. 2009.

- Bowman, Geoffrey. “On a Roll at Hadley.” In Burgess. Colin, Ed. Footprints in the Dust. The Epic Voyages of Apollo 1969-1975. Lincoln and London: The University of Nebraska Press. 2010.

- Burkhalter, Bettye B., and Sharpe, Mitchell R., “Lunar Roving Vehicles: Historical Origins, Development and Deployment.” Journal of the British Interplanetary Society, Vol. 48, pp. 199-212. 1995.

- Byrne, Malcolm, ed. The 1956 Hungarian Revolution: A History in Documents. A National Security Archive Electronic Briefing Book November 4, 2002. The National Security Archive, The George Washington University. http://www.gwu.edu/~nsarchiv/, http://www.gwu.edu/~nsarchiv/NSAEBB/NSAEBB76/. Accessed October 4, 2010.

- Central Intelligence Agency, “Report on Hungarian Refugees.” https://www.cia.gov/library/center-for-the-study-of-intelligence/kent-csi/vol2no1/html/v02i1a07p_0001.htm. Accessed October 4, 2010.

- Cernan, Eugene, and Davis, Don. The Last Man on the Moon. New York: St, Martin’s Press. 1999.

- Chaikin, Andrew. A Man on the Moon. Volume III: Lunar Explorers. Alexandria, VA: Time-Life Books, 1999.

- Hurt, Harry III. For All Mankind. New York: The Atlantic Monthly Press. 1988.

- Irwin, James B., and Emerson, William A, Jr. To Rule the Night. Philadelphia and New York. A. J. Holman Company. 1973.

- Jones, Eric M., and Glover, Ken, Editors. Apollo Lunar Surface Journal. Copyright © 1995-2010 by Eric M. Jones. Last modified: 11 September 2010. www.hq.nasa.gov/alsj/frame.html.

- Kranz, Gene. Failure is Not an Option. New York: Simon and Schuster. 2000.

- MacKinnon, Douglas, and Baldanza, Joseph. Footprints. The 12 Men who Walked on the Moon Reflect on their Flights, Their Lives, and the Future. Washington, D.C.: Acropolis Books Ltd. 1989.

- Morea, Saviero F. “The Lunar Roving Vehicle – Historical Perspective.” The Second Conference on Lunar Bases and Space Activities of the 21st Century, volumes 1 and 2. Conference held in Houston, TX, 5-7 Apr. 1988. NASA Scientific and Technical Information Program 1992. pp. 619-632.

- Murray, Charles, and Cox, Catherine. Apollo: The Race to the Moon. New York: Simon and Schuster. 1989.

- Oberth, Hermann. The Moon Car. Translated from the German by Willy Ley. New York: Harper and Brothers. 1959.

- Scott, David, and Leonov, Alexei. Two Sides of the Moon. New York: St, Martin’s Press, Thomas Dunne Books. 2004.

- Vaughn, Simon A. “Worth the Wait.” In Burgess. Colin, Ed. Footprints in the Dust. The Epic Voyages of Apollo 1969-1975. Lincoln and London: The University of Nebraska Press. 2010.

- Watkins, Billy. Apollo Moon Missions: The Unsung Heroes. Westport, CT: Praeger. 2006.

- Wright, Mike and Jaques, Bob, Editors. Morea, Saverio, Technical Editor. A Brief History of the Lunar Roving Vehicle. Produced by the Internal Relations and Communications Department, Customer and Employee Relations Directorate, Marshall Space Flight Center a Part of the History of the NASA Marshall Space Flight Center, Huntsville, Alabama. NASA April 3, 2002.